At SER, our mission is to help our customers maximize production and avoid downtime. Our goal is to deliver measurable results in a safe, prompt and professional manner by providing specialized industrial services.

Alongside our partners, we provide custom heater revamping services, reliability-focused oil flushing and robotic cleaning of cooling towers and tanks as part of a maintenance shutdown, turn around, during an emergency outage or when servicing an asset that remains operational. SER is focused on helping to keep our client’s plant, equipment and assets operational, productive and profitable.

SER improves process efficiency by eliminating fouling (upstream, downstream and process), reducing maintenance costs, energy consumption, enhancing production and extending asset integrity and asset life.

Our Range of Industrial Services Include:

- Industrial Services

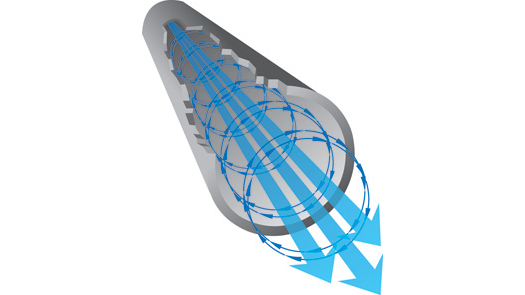

- High-Velocity Chemical Cleaning and Oil Flushing

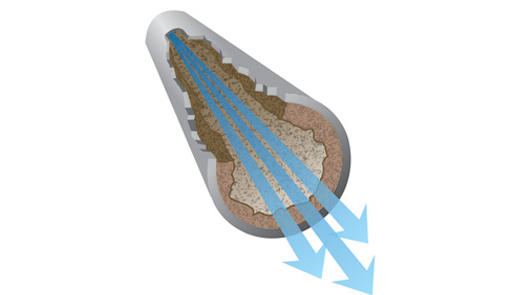

- Oil & Gas Pipelines De-oiling (4 inches and less) for Production Enhancement, Abandonment, and Decommissioning

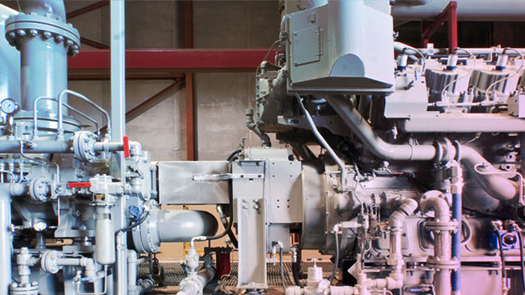

- Rotating Equipment Auxiliaries Pipe Decontamination, Heat Exchangers, Lube Oil System

- Oil and Cooling System Decontamination for Flow Enhancement

- Oil and Gas Pipeline Descaling (for Produced Water Pipeline)

- Industrial Process Equipment Services

- Hot oil Heaters

- Air Pre Heaters

- Heat Exchangers

- Distillation Towers

- Boilers

- HRSG’s

- Condensers

- Steam Process Piping

- Ancillary Steam System Equipment applications